Solar Hall of Shame

Can you find the problem(s) with this design and installation?

Scroll down for the answer.

As your Independent Engineer or Owner’s Representative,

PV Pros ensures your projects are designed and installed correctly so they never appear on the Hall of Shame!

An independent and structured review of the drawings, specifications, & equipment will minimize your risk by uncovering deficiencies in project design and identifying difficulties that may arise during the construction and operational phases.

We conduct desktop reviews and on-site inspections to de-risk your solar and storage projects. Our engineers work alongside financiers and project teams to evaluate the entire asset lifecycle, helping you make sound investment decisions. Whether it’s a new project going through development & construction, or a system that has been in operation for years, we help you evaluate the asset’s value, strengths, and risks.

We have formal procedures to ensure the quality of an installation and uncover any issues affecting long- or short-term revenue generation of solar PV and energy storage systems. Inspections can occur during installation or at any point during the operation. Commissioning occurs at the end of construction, where we confirm your system is designed, installed, tested, and operating per the project specifications and owner’s expectations.

Accurate energy models are essential for financial modeling. If a conservative PVsyst underestimates the generation, the project loses value. If an aggressive PVsyst overestimates, the project is overvalued and you may have trouble servicing the debt. We have run thousands of performance models, as well as analysis on thousands of operational systems, so our modeling inputs are based on industry accepted standards and backed by real world data.

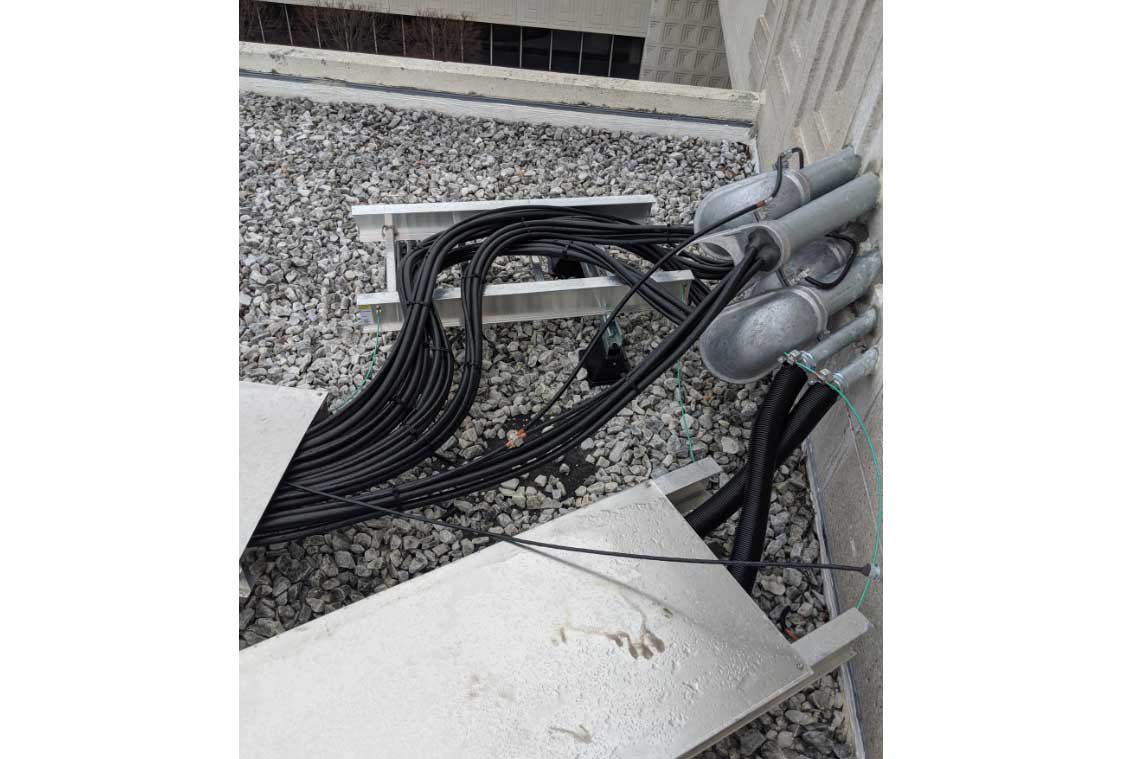

Conductors not protected from metal edge. With the conductors not secured, they are free to move back and forth against this edge until severed.

Split loom is not a permanent solution for abrasion protection. Even if UV rated, this will slide down and/or fall off.

Weatherheads are intended to be installed upright. Exposed ductseal will degrade and crumble withing a few years. Missing head cap.

Equipment Grounding Conductor (EGC) is not permitted to be black. NEC 250.119 requires it to be identified with a continuous outer finish (insulation) that is green or green with yellow stripe.

Cable tray is not secured to roof. Conductors are no secured to cable tray.

Unprotected & unsupported communication cable. Also insufficient insulation rating to be mixed in with higher voltage conductors.

Unsupported conductors

Industry standard is to have color or striping to identify positive and negative conductors.